What is 2K Stack Turning (SPIN) Mold?

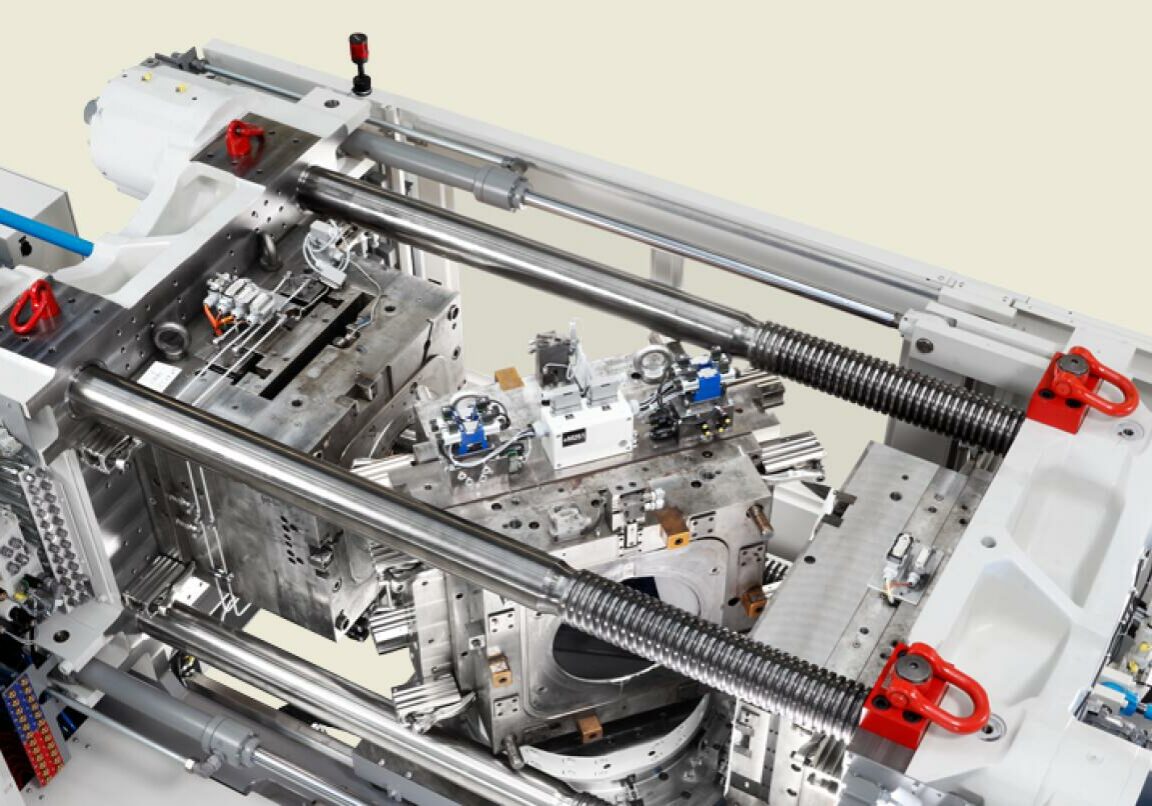

Multi-component parts can be manufactured in a cost-effective manner using special swivel plate SpinForm technology. The two mold parting lines are ideal for compression molding two-component parts.

The advantage of the SPIN STACK is that, for the same production lot, the size of the machine can be reduced.

In the stack turning technology, the mold rotation is performed with a horizontal rotary device in the form of a center plate. Plastic parts are produced in the first parting plane. When the mold is opened, they remain on the side of the moving center plate. For a fully opened mold, the center plate is rotated 180° and placed in the second parting plane. After closing again, the second component is injected in the second cavity where the parts are located on the center block.

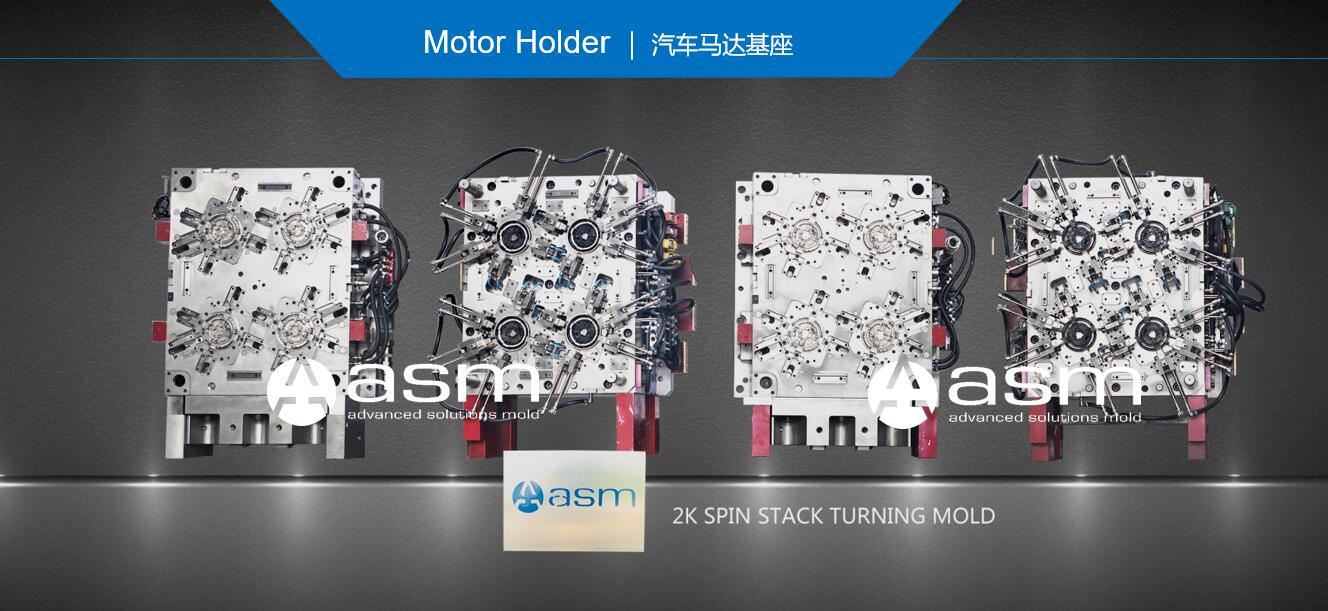

2K SPIN STACK (Stack Turning) Mold --- Projects Gallery